Regular service and repairs of split air conditioning systems are important to make sure your system provides the comfort and air cleanliness it did when first installed. Because the system always provides a comfortable living space, it is easy to forget it is there and to schedule regular servicing.

A regular service schedule, completed by an Alliance Climate Control service technician, can highlight any emerging issues and help prevent a mid-summer breakdown or need for repair.

Many homeowner insurance claims are related to water overflows, some from air conditioning systems. Most claims of this type can be avoided during inspections at regular scheduled services.

Large capacity HVAC systems can produce 110 – 190 Litres of water per day. Clogged drains with dirt, grime and mould must be checked at every regular service, to make sure they remain clear.

Priority task when servicing any air conditioning system:

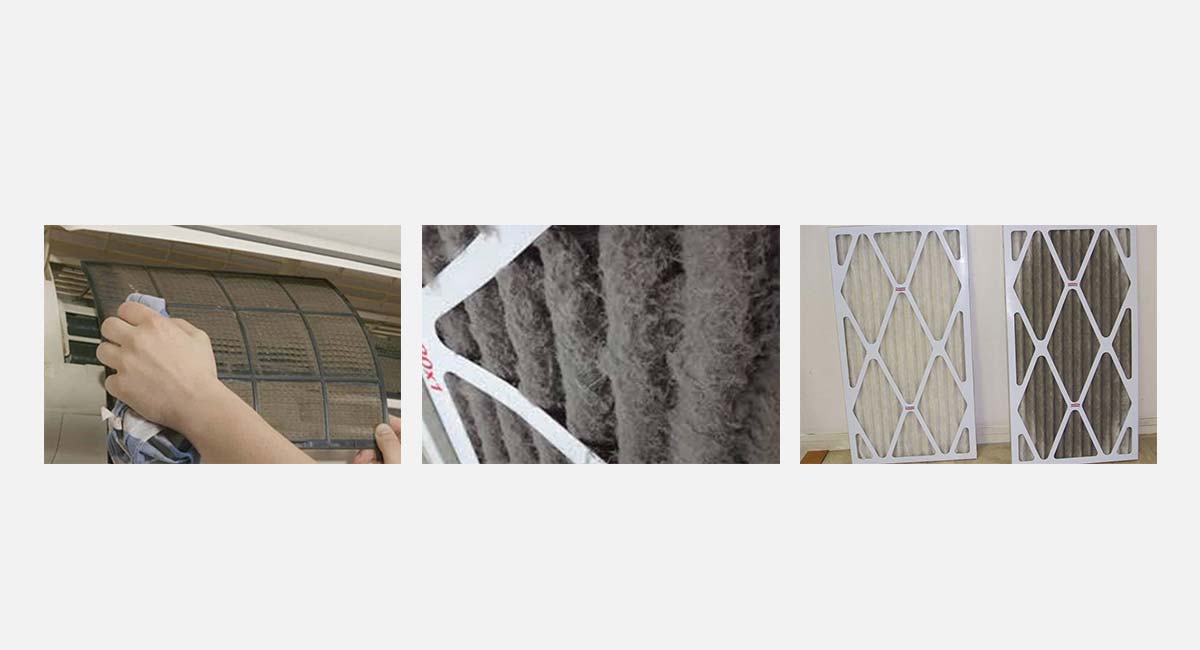

1. Filtration

A blocked air filter reduces system performance significantly. Air cannot pass a blocked filter freely, resulting in poor performance. To clean the filter, wash it in cold water and leave to dry completely before putting it back in the unit.

If the air filter cannot be cleaned, contact your Alliance service professional for the genuine replacement part.

Blocked filters can also cause drain blockages and water leaks, causing unnecessary water damage to your home. A complete drain flush is recommended at on every service to make sure all dirt, grime and mold is removed and the drain is clear. A blocked filter will prevent airflow and in severe cases may cause the indoor fan motor to burnout due to increased load.

2. Eco-Clean coil

- Over time the internal fan coil and blower wheels become partially impacted with dirt and grime. This can cause heat exchange failure, prevent the indoor fan coil from cooling itself with the movement of air, and increase the power requirements of the compressor. If the coil is blocked and airflow is reduced blower motor failure can occur, as reduced airflow causes high temperatures; the compressor will ultimately experience failure due to overheating.

- In the heat mode, a blocked fan coil may crack due to poor circulating airflow and eventually freeze over. This causes system overheating and results in premature component breakdown, usually at the compressor.

Eco-cleaning will remove mould, grime, bacteria and fungi, which in turn improves air quality, energy efficiency, and reduces power bill costs.

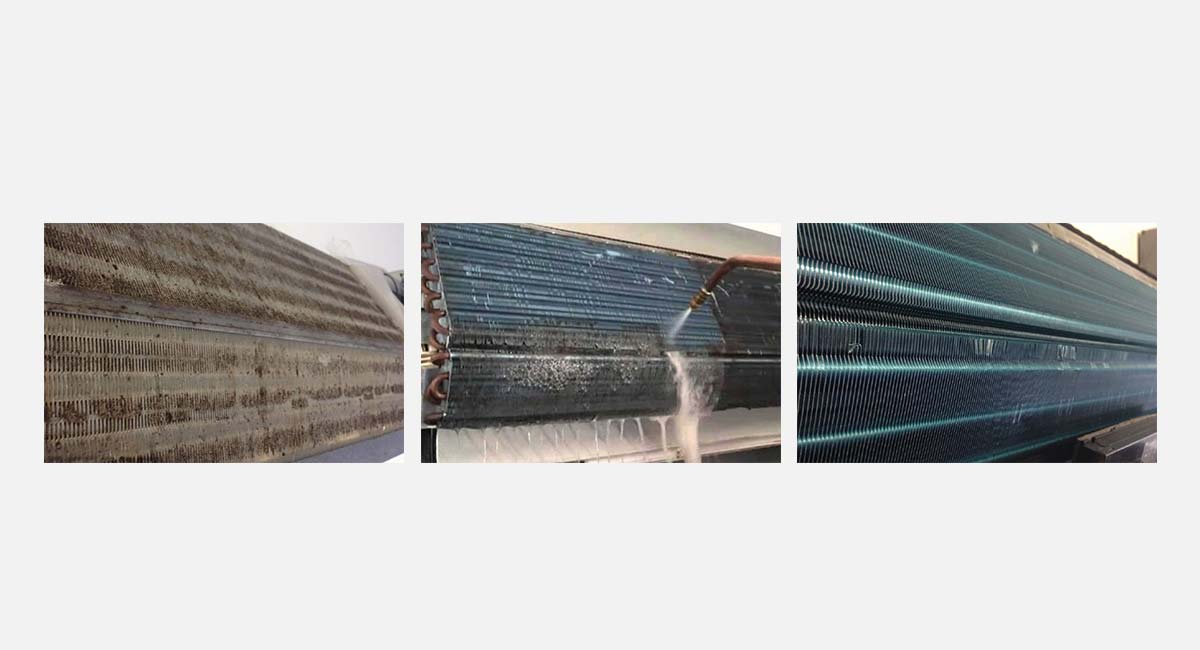

Before and after coil clean:

3. Condenser coil clean

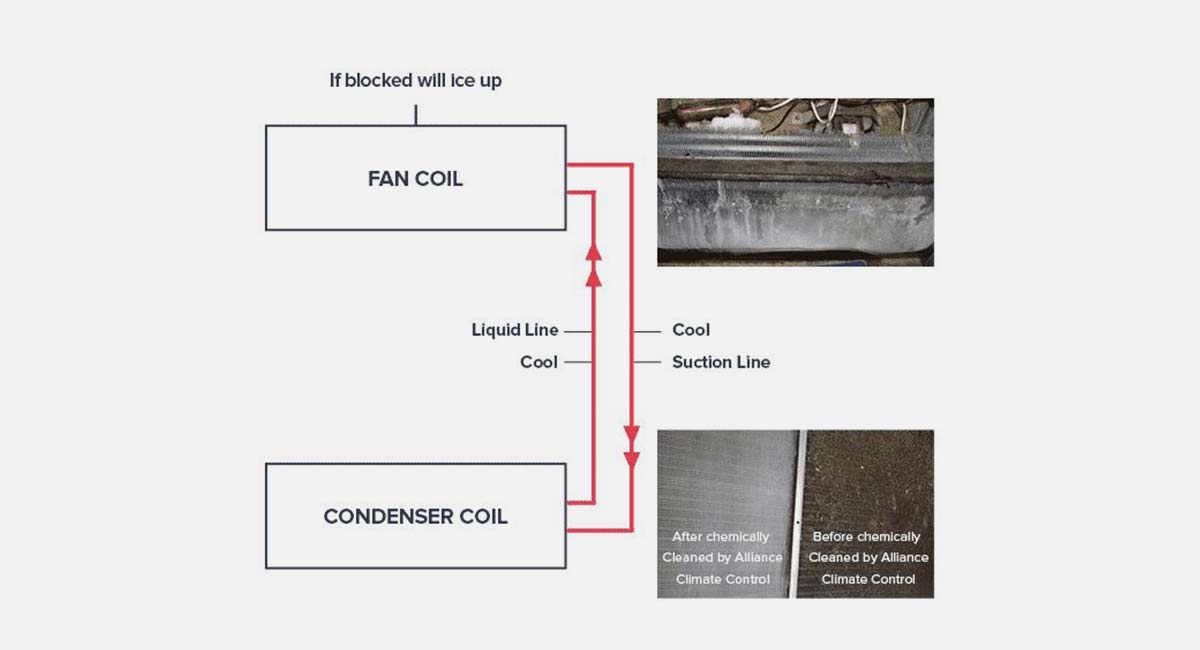

A blocked condenser coil is a danger to the liquid line:

- The liquid line needs to be cooled; if it’s hot due to a blocked coil, the liquid line will remain hot and the system will lose efficiency/performance.

- The liquid line will push warm liquid into the indoor fan coil and cycle back into the suction line, which is detrimental to the outdoor compressor (suction line must be cooled).

- The suction line will heat up and eventually, this will result in compressor burning out.

Indoor coil blockage, dirty filtration and partially impacted blower wheels will prevent airflow distribution from the coil; the outcome will be the coil icing up and condensation building up.

This can destroy the valves in the compressor and burn out the motor.

4. Circuit Breaker Size

A circuit breaker provides protection to a circuit when electrical equipment malfunctions and could prevent a fire or other catastrophic event.

In the event of operation of an air conditioner causing a circuit breaker to activate, it may indicate a problem with any part of the air conditioner including the compressor drive or condenser fan drive motor. It is important to identify the source of the problem first to confirm if the circuit breaker is malfunctioning or if the fault is within the air conditioner, or indeed if another appliance in the house.

A circuit breaker fault can be quite easily fixed by trained technicians. Checking for the fault with the right equipment ensures your continued safety and the technician responding to your call for assistance will be a fully qualified electrician.

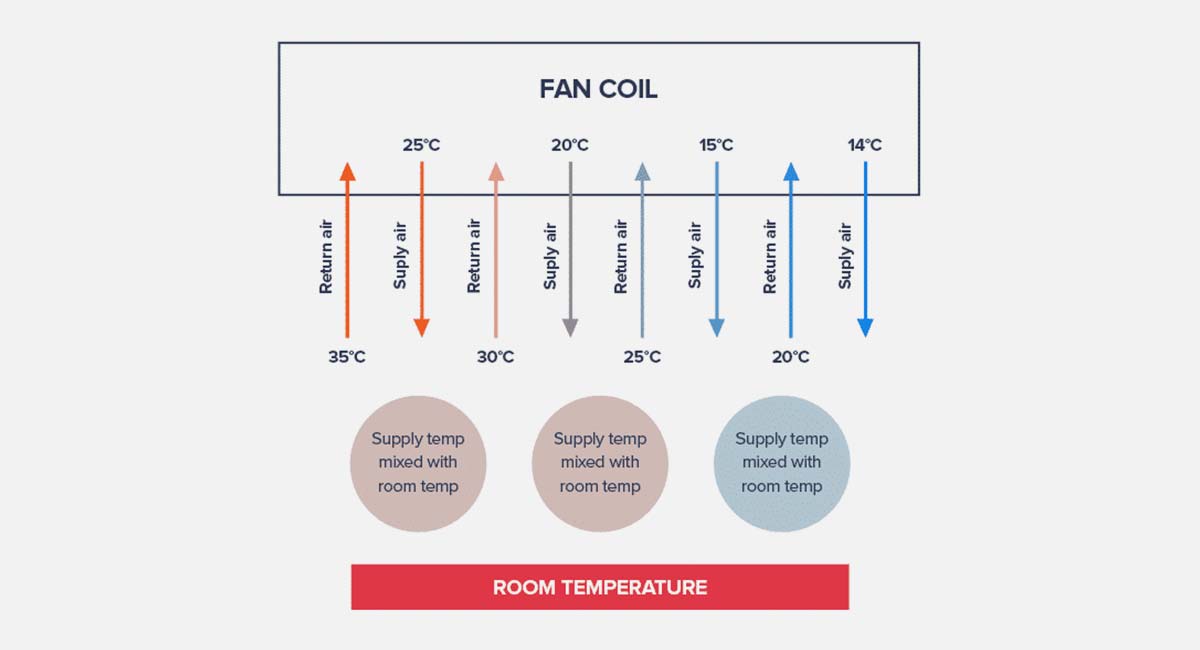

5. Right Temperature

- Set your air conditioner at the highest temperature setting, at which you still feel cool enough; 24°C is usually adequate. Each increase of the thermostat setting will save about 10% on your energy usage.

- Remember: the set point is the system cut out (the system will cycle off and have a break when it reaches set temperature). Whether you have the system set at 24°C or 18°C, the air coming off the coil is the same. When set on low temp. the air conditioning system will need to work hard and push more airflow to reach the set temperature; when setting on 24° the system won’t have to work as hard and will use less energy to reach that temperature.

- To achieve ultimate setpoint 24°C a 10°C temperature difference is required; to achieve 24°C you need to reach 14°C off the coil. To achieve 14°C or cooler off the coil, the unit must circulate the room temperature until room temperate becomes 24°C.

For example, if room temperature starts at 35° it would have to be circulated and pushed out from the coil at approx. 25°C, bringing room temperature to 30°C. The same process would have to be repeated until room temperature becomes 24°C, which indicates off coil air of 14°C. The correct temperature difference on correctly sized systems should be around 10°C. to 12°C. - Homes are not completely sealed units like a refrigerator, this is the reason why it is hard to achieve an extremely low indoor temperature (17°C); cool air escapes and hot air enters. Keeping you home seal by closing all window, doors and blinds will help you reach a low comfortable temperature in extremely hot days.

6. Low refrigerant charge

A refrigerant is a substance used in a heat cycle to transfer heat from one area and remove it to another. Usually a gas at room temperature. Found in pretty much everything that cools, and sometimes in things that heat, most commonly air conditioners, fridges, freezers, and vehicle air conditioners.

One of the most common air conditioning problems is having low refrigerant. This eventually makes your air conditioner to stop sufficient cool air and hence it becomes ineffective in its operations. An air conditioner on low gas or with gas leakage may be caused by faulty installation, poor servicing and poor maintenance. Once detected, the gas must be recharged if leak a is detected it should be repaired as soon as it occurs. This is because continued use of a leaking air-conditioner poses some dangers on the occupants of the specific building, the air conditioner itself and the environment as well.

One danger includes Damage to the air conditioner.

One of the immediate effects of using an air conditioner despite detecting the low gas or leak is damage to the whole device. This is because undue pressure is put on the compressor and this damages it. The compressor may break down due to overheating and as a result, the entire condensing unit is damaged. This may require you to repair the whole device instead of just the leak alone, which is quite costly.

7. Capacitor

We may need to replace your secondary motor controller, and here’s why.

The Capacitor regulates the voltage that runs the most expensive parts of your condenser, the compressor and the fan motor. As your secondary controller gets worn out it can send either too much or not enough voltage to these motors and burn them up.

If your capacitor fails it will either send too much or not enough voltage to your main motors and burn them up. A capacitor is made of bi-metal products and is bathed in oil to dissipate heat. We recommend our premium capacitor, which are filled with mineral, or petroleum based oil. Avoid Chinese made controllers, they utilize vegetable oil and will fail under duress and heat.

- Your compressor is right here and it would cost about $4,000 + to replace.

- And your fan motor is located here and it would be about $1,000 + to replace it.

- Now the controller is, and only between $190-$350 including installation and warranty.

Most customers choose to protect their most expensive motors this way and prolong their system live by replacing the capacitor, makes sense doesn’t it?

Related Articles